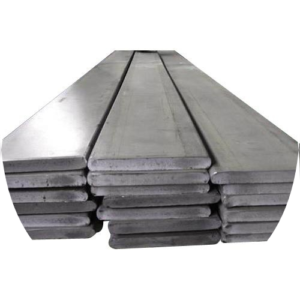

Stainless Steel 316 / 316L Patta & Patti, SS 316 / 316L Patta Steel Patti, ASTM A240 316 / 316L Stainless Steel Patta Patti, SS UNS S31600 / S31603 Patta Patti, SS DIN 1.4401 / 1.4436 / 1.4404 / 1.4435 Patta Patti Supplier in India.

Sagar Tubes (India) is a known Manufacturer and Supplier of SS 316 / 316L Patta Patti, which are molybdenum-bearing austenitic stainless steels. Purchase 216 / 316L Stainless Steel Patta Patti at exceptionally competitive price from us. Type 316 / 316L Patti is more resistant to atmospheric and other mild kinds of corrosion than the 18-8 stainless steels. Basically, media that do not corrode 18-8 stainless steels will therefore not attack these molybdenum-containing grades. AISI 316L Patta has properties similar to SS 316 except with a very much lower carbon content that reduces susceptibility to sensitization during welding. These AISI Type 316 / 316L Stainless Steel Patta are similar to 304 and 304L, but along with the addition of molybdenum. The addition of molybdenum improves the alloys corrosion resistance, especially with higher resistance to pitting and crevice corrosion in chloride environments. Stainless Steel 316 / 316L Patti is austenitic stainless steel bearing molybdenum which are profoundly resistant to general corrosion and pitting / crevice corrosion than the conventional chromium nickel austenitic stainless steel, for example, Type 304 Stainless Steel. Stainless Steel UNS S31603 Patti possess a higher percentage of nickel than SS 304. This alloy is Subject to pitting and crevice corrosion in warm chloride environments, and also to stress corrosion cracking above about 60 Degree C. Stainless Steel DIN 1.4404 Patta / Patti is often used in process streams containing chlorides or halides. They provide magnificent pitting resistance and good resistance to most chemicals engaged in the paper, textile and photographic industries

AISI 316L Stainless Steel Patta Patti is non-magnetic in the annealed condition but may turn out to be slightly magnetic because of welding. Additionally, Grade 316 / 316L Stainless Steel Patta provides remarkable elevated temperature tensile, creep and stress-rupture strengths, and also outstanding formability and weldability. Common industrial sectors of Grade 316 / 316L Patta Patti are Brewing, Chemical Industry, Dairy, Food processing, Marine equipment, Petrochemicals and Pharmaceuticals. Compared to chromium-nickel austenitic stainless steels, Type 316 / 316L Stainless Steel Patta provides very high creep, stress to rupture and tensile strength at elevated temperatures.

Basic uses for ASTM A240 Stainless Steel 316 / 316L Patti include in the construction of exhaust manifolds, furnace parts, heat exchangers, jet engine parts, pharmaceutical and photographic equipment, valve and pump parts, chemical processing equipment, tanks, evaporators, pulp, paper and textile processing equipment and any parts exposed to marine environments. The austenitic structure permits excellent toughness, even down to cryogenic temperatures. This ASTM A240 Stainless Steel 316 / 316L Patti has magnificent weld-ability, with or without the addition of filler metal.

You can get the exact material according to your requirement at the least possible price. We also provide Reworks, FOB, CFR, CIF, and door to door delivery prices. The materials we offer are completely verifiable, right from raw material test certificate to the final dimensional statement. E-guarantee to give a response within 24hours working hours (usually in the same hour).You can also get stock alternatives, mill deliveries with minimizing manufacturing time. We are completely dedicated to our customers. If it will not possible to meet the customer requirements after examining all options, we will not mislead by making false promises which will create good customer relations.

| Dimensions | : | ASTM, ASME |

| Standard | : | ASTM A 240, ASME SA 240 |

| Thickness | : | 1 MM To 100 MM |

| Hardness | : | HRB 62 to 180 – HV 140 to 1250 |

| Tensile Strength | : | As required up to 1450MPA |

Chemical Composition of SS 316 / 316L Patta & Patti:

| Element | C | Cr | Mn | Ni | P | S | Si |

|---|---|---|---|---|---|---|---|

| SS 316 | 8-11 | 18-20 | 2 Max | 8-12 | 0.045 Max | 0.03 Max | 1 Max |

| SS 316L | 0.08 | 18 Max | 2 Max | 14 Max | 0.045 Max | 3 Max | 0.10 Max |

Mechanical Properties of SS 316 / 316L Patta & Patti:

| Element | Tensile Strength | Yield Strength | Elongation | Density | Melting Point |

|---|---|---|---|---|---|

| SS 316 | Psi – 75000 | Psi – 3000 | 35 % | 8.0 g/cm3 | 1454 °C (2650 °F) |

| SS 316L | Psi – 75000 | Psi – 3000 | 40 % | 8.0 g/cm3 | 1400 °C (2550 °F) |